Patents and Patent Applications Related to Flute Construction

This page shows images of flute-related patents, design patents, and public patent applications filed with the

United States Patent and Trademark Office.

The patents are listed in chronological order:

Organ-Pipe

[Boardman 1848]

U.S. Patent 5,520, David Boardman, April 18, 1848.

Excerpt: … My improvement consists in placing a

partition of coarse cotton cloth, or other

proper substance punctured with holes,

across the chamber B and just above the air

induction entrance a. The said partition is

shown at b. It is made to divide the chamber

B into two parts C and d. When air is

blown through the passage a, and into the

pipe it will first pass into the space c, below

the cloth partition. From thence it will rush

through the meshes of cloth or between the

threads of which it is composed, and find its

way into the space d, from which it will pass

out of the opening e. By means of the partition

of cloth the air is divided into a great

number of small streams before it rushes

out of the eduction passage e. By such division

or by some other cause not known the

tone of the pipe is very highly improved.

Flute

[Pfaff 1857]

U.S. Patent 17,054, John Pfaff, April 14, 1857.

Excerpt: … placing the

mouth-pieces of flutes at right angles, or

thereabout, to the stems or bodies, in order

that greater convenience may be afforded to

the players, and the distortion of arms, fingers, and neck required in playing upon

flutes of the ordinary construction, may be avoided.

Improvement in Fifes

[Pfaff 1864]

U.S. Patent 45,270, John Pfaff, November 29, 1864.

Excerpt: … forming a ridge

or protuberance at each side of the month-opening of a fife, the said ridges enabling the

performer to readily adjust the instrument to his lips, and to maintain it in its adjusted position without the care and effort required to

accomplish the same result with ordinary fifes.

Improvement in Flutes

[Berteling 1868]

Patent 76,389, Theodore Berteling, April 7, 1868.

Flute

[Giorgi 1897]

U.S. Patent 594,735, Carlo T. Giorgi, November 30, 1897.

Method for Shaping Metal Tubing

[Christensen-N 1922]

U.S. Patent 1,432,279, Nils Christensen, October 17, 1922.

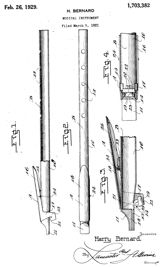

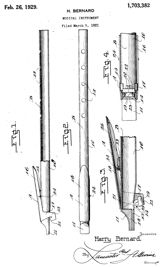

Musical Instrument

[Bernard 1929]

U.S. Patent 1,703,382, Harry Bernard, February 26, 1929.

Nose Flute

[Davis 1941]

U.S. Patent 2,245,432, Ernest W. Davis, June 10, 1941.

Design for a Whistle

[Frantzius 1945]

U.S. Design Patent D141,400, Peter von Frantzius, May 29, 1945.

Wind Instrument

[Tremaine 1967]

U.S. Patent 3,326,073, Daniel V. Tremaine, June 20, 1967.

Cylindrical Flute

[Sandner 1973]

U.S. Patent 3,763,737, Erich Sandner, October 9, 1973.

Abstract: The specification describes a flute with a cylindrical bore whose blowing end is closed by a transverse wall at or behind the embouchure (the labial in the case of a recorder-type flute or the blowing hole in the case of a transversely blown flute). The flute is provided with means for correcting the sound of the flute so as to obtain the pure tonality which would otherwise not be obtained owing to the cylindrical bore of the flute.

Fipple Flute

[Johnson 1974]

U.S. Patent 3,815,466, Paul Conrad Johnson, June 11, 1974.

Abstract: A fipple flute includes an oyster shaped hollow body providing a resonant chamber, a whistle type mouthpiece in the rim of the body chamber communicating with the resonant chamber and with the exterior through a slit in the body, and four pitch control openings in the resonant chamber of differing sizes, disposed at each side of a diametral plane through the body intersecting the mouthpiece and perpendicular to the rim plane, the holes spaced so as to be simultaneously engageable by fore finger and middle finger of each hand of the musician, the pitch hole sizes and locations relative to the resonant chamber enabling a full octave western chromatic scale of thirteen notes to be sounded without overblowing, an eyelet at the rim opposite the mouthpiece being provided with a necklace for carrying the flute. The four pitch control holes are disposed as at the corners of a trapezoid adapting same to a mnemonic musical notation consisting of a quartered square with shaded quarters corresponding to holes to be stopped. The body is made in two halves initially separated along the rim and glued together; polyester resin being the body material and the glue of the same material. After joining the halves, the glue flash is trimmed and the instrument tuned by pitch hole reaming or filling. Decorative exterior finishes are applied.

Cylindrical Head Joint with Acoustic Wedging for Concert Flutes

[Fajardo 1977]

U.S. Patent 4,058,046, Raoul J. Fajardo, November 15, 1977.

Abstract: A cylindrical head joint has an internal cross-section that tapers down from a cylindrical shape at the tenon to a non-cylindrical shape at the embouchure end by means of a wedge internally bonded to the cylinder. The relative tuning of the three octaves of the flute can be achieved by varying the position of the wedge either rotationally or longitudinally inside the cylinder. The laborious method of tapering the head by forced shrinking of a cylindrical tube is thus avoided and a superior tone quality is achieved because the air jet that enters the embouchure hole hits a non-cylindrical wall which has a favorable effect on transient sounds and harmonics.

Fipple Flute

[Mumford 1981]

U.S. Design Patent D258,364, Bryan D. Mumford, February 24, 1981.

Abstract: The ornamental design for a fipple flute, as shown.

Hand Flute and Percussion Instrument

[Cantos 1981]

U.S. Patent 4,269,104, Earl J. Cantos, Jr., May 26, 1981.

Abstract: A musical instrument of the woodwind type in combination with a raised oblong resonance chamber, said instrument configured in the shape of a human hand. The resonance feature is utilized by placing the oblong or blister-like protrusion against the cheek of a user which, when tapped on its opposite side achieves tonal variations as a function of size variation and degree of modulations of the oral cavity. The woodwind function is achieved by blowing through a mouthpiece (the thumb digit) and egress of wind passing through the finger hole portions of the remaining four finger digits.

Obturator for Flute Designed to Improve the Emission of Certain Notes

[Ferron 1985]

U.S. Patent 4,499,810, Errnest J. Ferron, February 19, 1985.

Abstract: The invention relates to an obturator designed to close the cavity provided next to the mouthpiece hole of a flute or similar instrument, which obturator comprises one auxiliary resonator issuing into the column of air and produced in the form of a chamber the length of which can be adjusted to improve the emission of at least one particular note of the instrument.

Flute

[Strathmann 1987]

U.S. Patent 4,664,011, Arnfred R. Strathmann, May 12, 1987.

Abstract: A flute is described having the mouthpiece, the shape and the dimensions of a recorder but is however provided with a key mechanism similar to that of a saxophone. The buttons, keys and tone holes are however adapted to the special features of sound generation by a recorder.

Piccolo Flute

[Braun 1987]

U.S. Patent 4,714,000, Anton J. Braun, December 22, 1987.

Abstract: A piccolo flute, in particular a piccolo transverse flute of the family of the "orchestra Boehm flutes", having a head part with a mouth hole, also called an embouchure hole, a closure cap with an adjustable seal on its free frontal end and a body part with finger holes and a key mechanism. The terminal finger hole is located on the free frontal end. The body part has only one C hole. The invention provides a novel hole setting scheme for a concert pitch tuning of a'=440 Hz. The axis of the C hole encloses with the longitudinal center plane of the body part containing the majority of the finger holes an angle of 120.degree. to 130.degree..

Pentatonic Ocarina

[Fowler 1990]

U.S. Patent 4,893,541, Ilania H. Fowler and J. Charles Hind, January 16, 1990.

Abstract: An ocarina includes a generally oval body enclosing a hollow chamber, a mouthpiece, a passageway connecting the mouthpiece and the chamber, a vent slot against which the air within the chamber may vibrate, and a plurality of pitch control holes. By covering or uncovering the pitch control holes with his or her fingers, the user of the ocarina can produce the notes of the pentatonic scale. Alternate embodiments of the ocarina can be produced for playing tones within the soprano, alto, tenor or bass tonal range. The device can also be configured to have three pitch control holes per enclosed chamber, or to include two enclosed hollow chambers of air, but in any configuration, the instrument can only produce the notes of the pentatonic scale.

Flute Headjoint

[Goosman 1990]

U.S. Patent 4,896,579, Jack P. Goosman, January 30, 1990.

Abstract: A flute headjoint having superior playing characteristics, said headjoint comprising a lip plate coupled to a headjoint tube by means of a chimney, the lip plate, chimney bore and headjoint tube having apertures aligned to form an air passsageway, the lip plate and chimney forming an embouchure wall having a top surface, a rear surface and a front surface which splits the stream of air from a flute player's lips into a first air stream which flows into the air passageway and a second air stream which flows over the top surface of the embouchure wall. The rear portion of the lip plate is shaped so as to channel the second air stream downwardly and towards the middle of the lip plates rear portion. Flutes fitted with such a headjoint are believed to have quicker attack, cleaner tonal qualities, and greater sound volume while retaining flexibility of play.

End Blown Flute with Standard Keying

[Wesley 1991]

U.S. Patent 5,014,585, Sam Wesley, Sr., May 14, 1991.

Abstract: An end-blown flute comprising a hollow tube open at both ends with an embouchure at the upper end of the tube to provide an end-blown free air-reed. The tube has at least 13 tone holes through the side wall thereof, the holes being particularly spaced from the bottom of the tube so that keys can be mounted in the tube in the same pattern as on a standard transverse flute and so that the end blown flute can be played with the same fingering system used with a standard transverse flute. The embouchure has a U-shaped opening which opening which opens into the upper end of the flute and also exposes the upper forward edge of the flute tube, making it easier for the player to get into the third register.

Flute Headjoint

[Drelinger 1992]

U.S. Patent 5,105,705, Sanford Drelinger, April 21, 1992.

Abstract: A flute headjoint having a lip plate in which a portion of the blow edge is stepped to impart different heights to the blow hole. The blow hole has an inward protrusion beginning at the blow edge and extending the height of the blow hole to impart a region of narrower transverse dimension to the blow hole. Either feature, or both together, improve upper register performance. The edge of the lip plate opposite the lip rest surface is swept back toward the lip rest surface to minimize obstruction of excessive air flow. The blow hole features are incorporated in a piccolo embouchure including a tubular body of two halves.

Flute Mouthpiece with Adjustable Core Gap

[Strathmann 1992]

U.S. Patent 5,107,740, Arnfred R. Strathmann, April 28, 1992.

Abstract: In a flute mouthpiece the core has an upper section which points towards the interior of the mouthpiece, which is pivotably journalled and which can be adjusted in the vertical direction by an adjustment bar which is led out of the flute mouthpiece. In this flute mouthpiece the size of the core gap can be varied by the adjustable section so that a fine adjustment of the tone of the flute can be effected.

Mouthpiece of Flute

[Yamauchi 1993]

U.S. Patent 5,261,308, Genhichi Yamauchi, November 16, 1993.

Abstract: In a mouthpiece of flute, a projective tongue piece is formed in a position where the inner surface of a hole on the side on which a lip is to be put meets the inner surface of a head pipe so as to form a bulgy rounded concaved surface which is made to bulge outwardly of the head pipe, so that the interior space of the pipe is divided by the projective tongue piece into two pats including an acoustic space and a fluid space. In order to make is possible to give a clear, vigorous, rich and loud sound easily as well as to give high-pitched tones without difficulty, the inner surface of the head pipe in the vicinity of the hole comprises a rounded raised portion which is so formed as to draw a smooth streamline for serving as the inner surface of the pipe and has a cross-sectional area equal to that of a space defined by the bulgy rounded concaved surface, and air screening dikes which are formed on both sides of the rounded raised portion, respectively.

Flute Mouthpiece

[Yamauchi 1995]

U.S. Patent 5,435,221, Genhichi Yamauchi, July 25, 1995.

Abstract: In a flute mouthpiece in which the inner surface of a hole on this side, on which the lip is to be placed, is made to extend downward into a head pipe to form, on the inner wall of said head pipe, a projecting tongue, the lower surface of which is formed by a concave curved surface and in which the interior space of said head pipe is divided into two parts including an acoustic space and a fluid space, a concave portion having a cross-sectional area equal to that of said projecting tongue is provided on the lower portion of said inner surface of said head pipe which is continuous to said concave curved surface, so that the straight travel property of a sound is enhanced by an interference of a sound wave and the efficiency of exhalation converting its energy to a sound is enhanced, thereby making it possible to obtain a clear, vigorous, and rich quality sound. In addition, since the high-pitched tones of the scale of the flute cannot possibly be not true and a sound cannot possibly be confined inside, a sufficiently clear, vigorous, rich, and loud quality sound can be obtained.

Flute

[Light 2000]

U.S. Design Patent D427,228, Ken Light, June 27, 2000.

Abstract: The ornamental design for a flute, as shown and described.

Lung Flute

Patients who suffer from chronic obstructive pulmonary disease rely on medications and strenuous coughing to help break up the thick gobs of mucus clogging their lungs.

The Lung Flute take another approach: 15 to 20 puffs of air into the Lung Flute. Blowing into the reed instrument sends a steady 16-hertz vibration into a user’s chest, dislodging mucus in the lungs so that it’s easier to cough up.

- Device and Method for Inducing Sputum, [Fowler-Hawkins 2004]

, U.S. Patent 6,702,769 B1, Sanford Elliot Fowler-Hawkins, March 9, 2004. , U.S. Patent 6,702,769 B1, Sanford Elliot Fowler-Hawkins, March 9, 2004.

- Device and Method for Inducing Sputum and Collecting Samples, [Fowler-Hawkins 2006]

, U.S. Patent 6,984,214 B2, Sanford Elliot Fowler-Hawkins, January 10, 2006. , U.S. Patent 6,984,214 B2, Sanford Elliot Fowler-Hawkins, January 10, 2006.

- Lung Flute web site

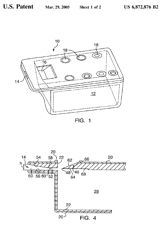

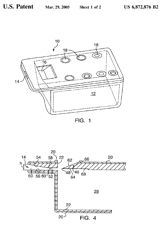

Ocarinas with an Inner Liner and an Outer Shell

[Ahrens 2005]

U.S. Patent 6,872,876 B2, Karl P. Ahrens, March 29, 2005.

Abstract: One embodiment of an ocarina has an inner liner that includes a plurality of apertures and an outer shell disposed substantially completely around the inner liner. In one exemplary embodiment of such an ocarina, the plurality of apertures in the inner liner facilitates the airflow communication through the inner liner to produce a tone when the ocarina is played,

whereas the outer shell provides a protective or ornamental envelope for the inner liner and includes a plurality of openings that register with the apertures in the inner liner. In another exemplary embodiment, an ocarina has a body having a plurality of apertures disposed therein.

The body is formed by an inner liner defined by at least one sound chamber and a first cooperating cover and an outer shell disposed substantially completely around the inner liner. The outer shell is defined by a vessel and a second cooperating cover, and some of the inner surfaces of the outer shell engage some of the outer surfaces of the inner liner to retain the inner liner in the outer shell in an interference fit.

Foster Extension for Flutes

[Williams-GI 2009]

U.S. Patent 7,476,793 B2, Gail I. Williams and David C. Williams, January 13, 2009.

Abstract: A flute attachment which improves and enhances the harmonic capability of a flute by lengthening the resonant chamber of the standing wave. The instant invention ‘fine tunes’ the harmonic range of the flute by taking into account the end point of the fundamental length of the sounding oscillations of an air column without negating the frequency which has been predetermined by the original terminus of the physical scale length of the flute. The sound wave length within a flute terminates slightly beyond the physical length of the flute tube and this difference in length is known as the ‘end correction’. The instant invention captures the node which extends beyond the flute tubing and balances and reinforces the propagation of upper partials throughout the sounding range of the instrument.

Single Holed Flute

[Wells 2009]

U.S. Patent Application 2009/0049977, Steve Wells, February 26, 2009.

Abstract: What is disclosed is a musical instrument that may be a single holed flute that has the tonal characteristics of a flute, but offers an infinite scale of available notes and pitch modification between the high and low limits of the single holed flute's tone production.

Woodwind Instrument

[Laukat-S 2009]

U.S. Patent 7,563,970 B2, Sheryl Laukat and Tevis Lukat, July 21, 2009.

Abstract: A method of improving the tonal characteristics of a woodwind instrument. The method includes identifying a position on the woodwind instrument, wherein placement of a tonal material thereto causes a lowering of overtone amplitude during play, by observing overtone characteristics during play; positioning the tonal material to the woodwind instrument; measuring the overtone amplitude; playing the woodwind instrument; and repositioning the tonal material to optimal overtone amplitude position; and attaching the tonal material to the woodwind instrument, at the optimal overtone amplitude position. The tonal material comprises one of the group consisting of: garnet, jasper, agate, aventurine, carnelian, citrine, fluorite, hematite, malachite, obsidian, onyx, tiger's eye, turquoise, unakite, moonstone, peridot, jade, alexandrite, amethyst, chalcedony, quartz, aquamarine, lolite, rhodolite, opal, topaz, tourmaline, tanzanite, diamond, emerald, sapphire, ceylon sapphire, ruby, woodwind, other metals, and combinations thereof.

End Blown Flute Having an Acoustic Air Space

[Rozier 2009]

U.S. Patent Application 2009/0293701, Claude Rozier, December 3, 2009.

Abstract: The present invention is directed to musical instruments that are based on the operation of an air reed and, in particular, encompasses end-blown flutes comprising an acoustic air space and a fluid air space. The communication between the acoustic and fluid air spaces is positioned so as to minimally interfere with the flow of air introduced, i.e., blown, into the fluid space and enables the instrument to produce rich, in-tune tones across a three octave range. The acoustic air space is formed by a hollow tuning chamber positioned opposite the air reed. In alternate embodiments, the invention encompasses a head-joint of a musical instrument, which head joint comprises a an acoustic space and a fluid space. The head joint of the invention may be used to replace or in place of the head joint or mouthpiece of common musical instruments of the woodwind family, e.g., the Western flute, saxophone, clarinet, oboe, nay, shakuhachi, or recorder.

|